We are here to help

Sometimes, units break. Fortunately, we have the expertise to fix them. Our APC-trained technicians expertly perform over thirty “checks” and reconfigurations to recertify units to APC specifications and add years to their lives. As the only company that has access to APC’s Engineering Change Orders, units leaving our shop often work better than the original.

30-Step Recertification Process

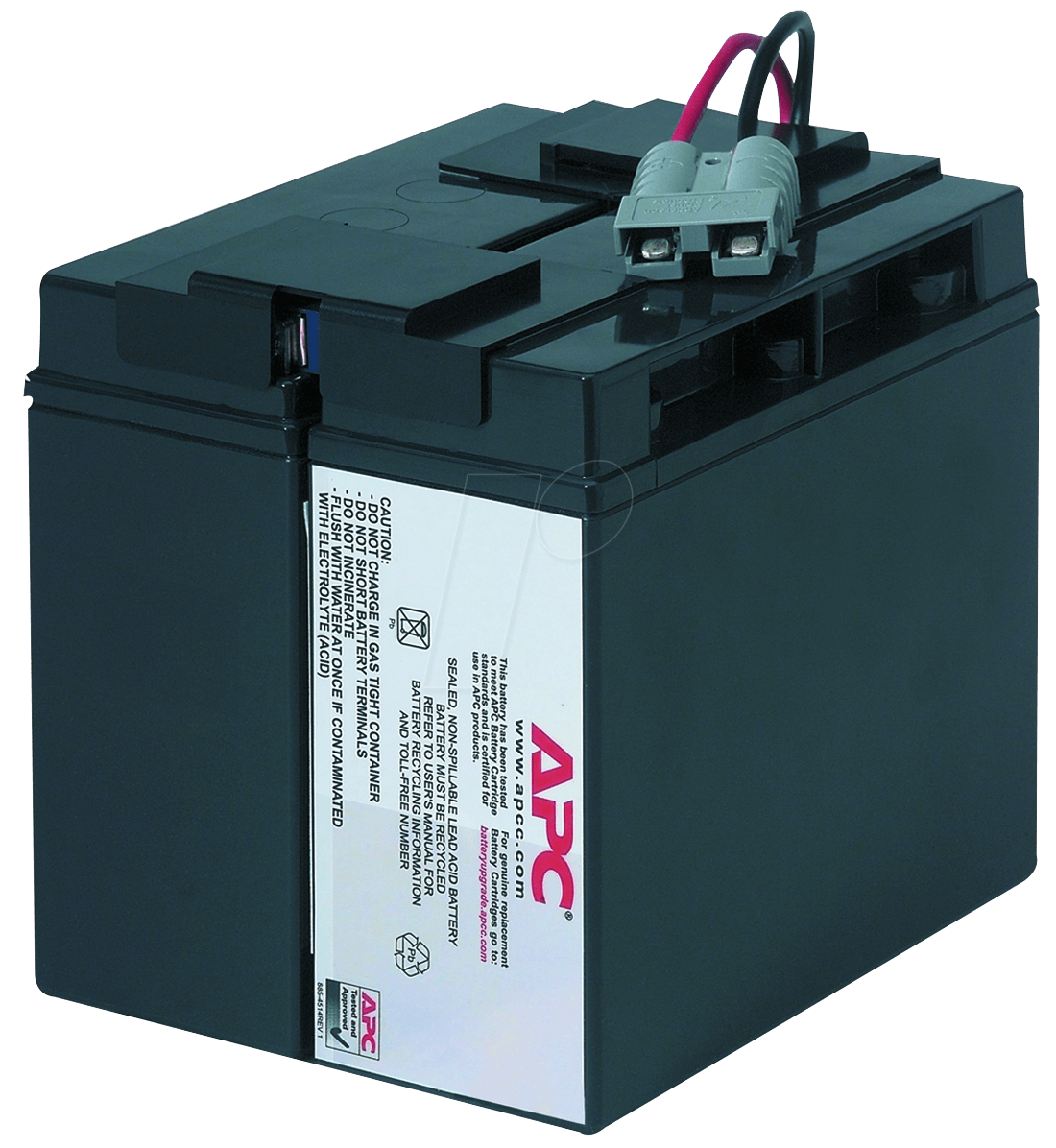

- Replace Batteries

- Inspect the unit for any component damage or excessive heat markings

- Replace any missing parts

- Verify charging circuit

- Adjust the charging circuit

- Check APC database for any engineering change orders

- Fix any cold solder joints or loose components

- Tighten all Fast-on connectors

- Check Earth Leakage

- Adjust AC Line Constant to ensure proper reading of the incoming AC Line

- Adjust all 4 Battery Constants

- Adjust Power Constant

- Performs Lights Test

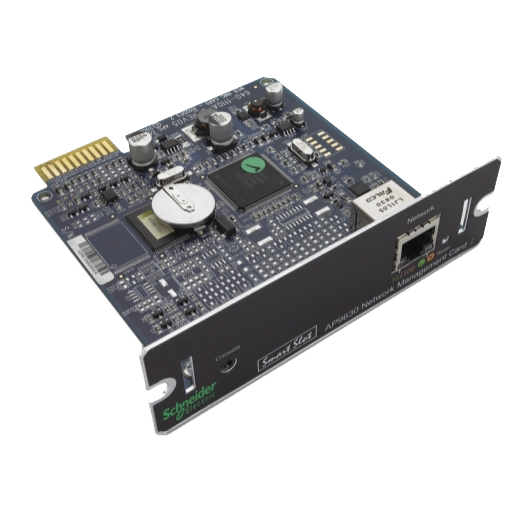

- Verify Firmware version and flash EPROM with new version or replace Microprocessor with new version

- Verify and adjust I/O constant

- Verify and reset UPS Identity code

- Reset Battery change date

- Verify the waveform of the output on the oscilloscope

- Verify transfer point to boost function

- Turn down input voltage farther to verify transfer points to full battery

- Turn up input voltage to verify transfer point to trim function

- Turn up input voltage further to verify transfer point to high voltage battery

- Adjust any transfer point as needed

- Load unit to 100% load and cut input power to ensure load stays up and waveform is stable

- Verify all push buttons are functioning properly

- Verify all bezels are properly attached and replace if necessary

- Verify integrity of all mounting brackets, if applicable

- Re-paint or replace covers

- Inspect to ensure all screws are properly installed and properly torqued

- Clean entire unit